Corrosion under Insulation (CUI):

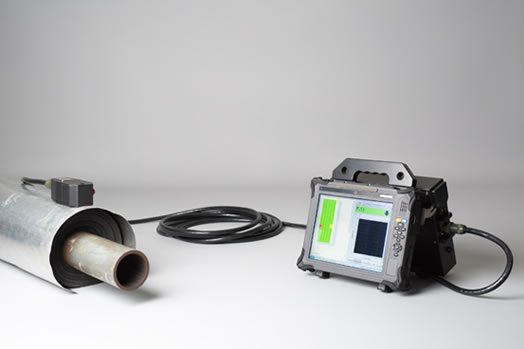

Pulsed Eddy Current (PEC) is an inspection technique for inspecting carbon steel objects such as pipes and vessels, without the need for contact with the steel surface. PEC can measure percentage variations in steel thickness through any non-conductive and non magnetic materials between sensor and surface such as air, insulation material, concrete, plastics, coatings, sea water and marine growth, paint, , deposits, oil, composite repairs, fireproofing, “scabs” aluminium sheeting and other nonmagnetic insulation covers; so ideal for Corrosion Under Insulation (CUI) application.

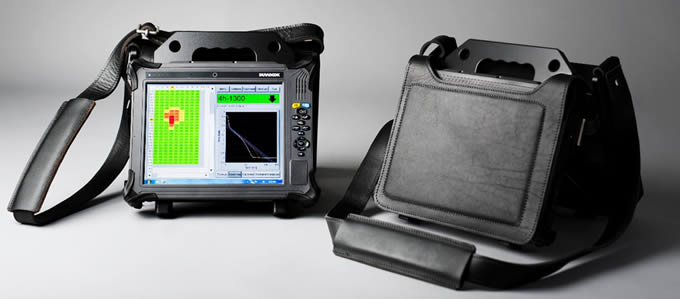

The MAXWELL PECT instrument is designed for the inspection of carbon steel and low-alloyed steels, which are magnetic. For magnetic test specimens, the eddy currents are concentrated on the surface directly after the magnetic pulse. Subsequently, the eddy currents diffuse into the test specimen, until the backwall is “found”. This results in a characteristic shape A-scan: a straight line, corresponding to the diffusion of the eddy currents, followed by curved section when the backwall is sensed. |

|

|

Tubing Inspection:

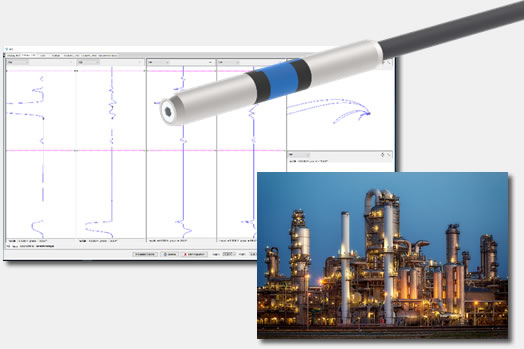

Numerous exchangers must be inspected with electromagnetic techniques such as Remote-Field, Near-Field, Eddy Current, etc. These techniques perform extremely well on all types of steel.

SG NDT Multi-technological instrument runs with IRIS, ECT, RFT and NFA offering unrivaled performance in the industry. Our capacity for working in Array mode for all above-mentioned techniques is a great advantage for Pipe inspections.

Eddy Current Array works very well for weld inspection. It is a great alternative to the standard tubing eddy current technique.

|

|

|