Equipment:

Wavemaker G4 Mini:

The latest Wavemaker® G4 Mini offers all of the traditional Wavemaker® features and some new ones in a small (22 x 30 x 13cm) and lightweight (4.5 kg) package.

The 'Fully Loaded' instrument is capable of working with all of the pipe and tube transduction systems produced by GUL. It is suitable for both the lower frequencies that are used for buried and coated pipes and the higher frequencies that are used with HD rings for support inspection and higher sensitivity to pitting. With one button press, the instrument can be placed into gPIMS Collector mode to allow a minimally trained operator to collect repeat data from a permanently installed gPIMS sensor.

The instrument has similar capabilities to the Wavemaker® G4 with the LF+MF option installed. However, it only contains 16 channels (compared to the 32 channels for the standard Wavemaker® G4); therefore you will need a pair of channel reducers when joining EFC or HD inflatable rings together to collect data on very large diameter pipes.

More information:

|

|

|

| |

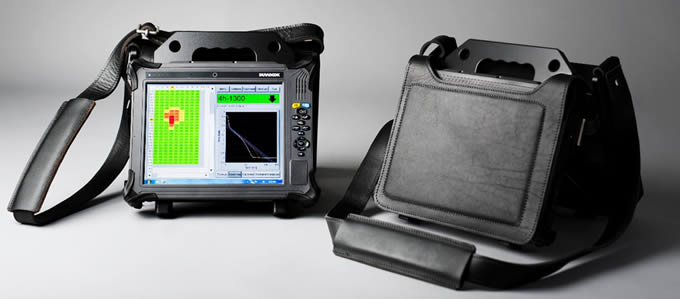

gPIMS Mini Collector:

The permanently installed gPIMS sensor rings are often installed in high risk/consequence areas that are difficult to access. The initial installation and pipe inspection is performed by a fully qualified inspector, who is able to classify the results and document the exiting features in the pipe, and set the optimal collection parameters for the inspections. However, once this initial inspection is complete, repeat inspections can simply be performed by plugging the instrument into the sensor's connection box and triggering the automatic collection sequence (which typically takes less than 5 minutes to complete).

The gPIMS® Mini collector is a dedicated instrument that can be used by operators with minimal training to perform the repeat collections. The data that the instrument collects can be uploaded to a central location where a qualified inspector can access the data, compare it to the previous data (using specially developed comparison software), and efficiently generate the required reports.

.More information:

|

|

QSR1:

he QSR1® is GUL’s new quantitative short range (QSR) device, incorporating the latest guided wave technology and hardware.

The system is designed to semi‑automatically scan predefined sections of straight pipelines for corrosion under pipe supports (CUPS).

The QSR1® can provide a quantitative measure of the average wall, as well as the remaining wall thickness down to half of the nominal wall thickness.

This instrument is suitable for motorised guided wave scanning on predefined sections of straight pipelines, with the added compatibility to operate with GUL’s cloud‑based platform.

More Information:

Brochure:

|

|

Pipe Inspection rings:

Compact rings:

The Compact® ring is the latest addition to the GUL guided wave transduction system which has been designed to be lightweight and low profile. This new system has been completely re‑engineered to build on everything that has been done before, while reducing weight by 35%, axial width by 30%, and radial height clearance to under 38mm.

This is an inspection system designed to tackle a wide range of inspection challenges including:

- Bare / Painted Pipes

- Sleeved or Unsleeved Road Crossing Pipes

- Buried Pipes

More information:

Brochure:

|

|

|

HD Rings:

The High Definition (HD) series of rings has been developed for applications where higher sensitivity and resolution are required. Such applications typically include interface penetrations, testing under supports and localised pitting.

Localised defects (such as pits) will be easier to detect at higher frequencies, however, erosion and certain patches of general corrosion are usually easier to detect at lower frequencies using the adjustable modules. In addition, testing at higher frequencies will cause the range to be significantly reduced in situations when there is an attenuative coating or general corrosion. Therefore, the HD rings accept both HD and Adjustable modules to cover the full frequency range depending on the pipe condition and anticipated defect type. However, HD modules cannot be used in standard EFC rings because there are not enough transducer positions to get reliable results.

The HD inflatable rings are available from 6 inches (nominal pipe size) and above; below this size, HD solid rings are available.

More information:

|

|

|

High temperature rings:

High Temperature (HT) rings and modules are similar to standard EFC inflatable rings but are capable of testing pipes operating at up to 350°C (660°F) provided that the ring is used in the manner specified in GUL's Standard Practice for GWT of High Temperature Pipe-work (GUL 207:2013).

In order to carry out the guided wave inspection, only a 50 cm (20 inch) wide strip of insulation needs to be removed. No couplant is required and the inspection can be performed while the pipe is still on line.

More information:  |

|

|

gPIMS:

In many situations, the cost of accessing a pipe is much higher than the cost of inspection. This access cost can make repeat inspections with removable rings prohibitively expensive. The environmentally robust gPIMS® range of sensors has been developed to be easily bonded to the pipe, sealed and then left in place. A cable connects the gPIMS® sensor to a connection box that can be located in a convenient, easy to access location.

By performing repeat inspections and comparing the results to previous inspections, operators can monitor for any change in the condition of the pipe. Frequent data collection significantly improves sensitivity and reduces false call rates compared to conventional guided wave testing.

More information:

|

|

|

| |

|

|

Brochure:

GUL full-product catalog:

|

|